I’m starting to go back and publish some some of my draft updates as well as finally getting around to updating my log to get more current. After moving the project to the hangar, I didn’t have as much motivation to update my log in the last six months. Between COVID, work, home, and trying to get time to work at the airport, publishing updates to the log fell to the bottom of my list.

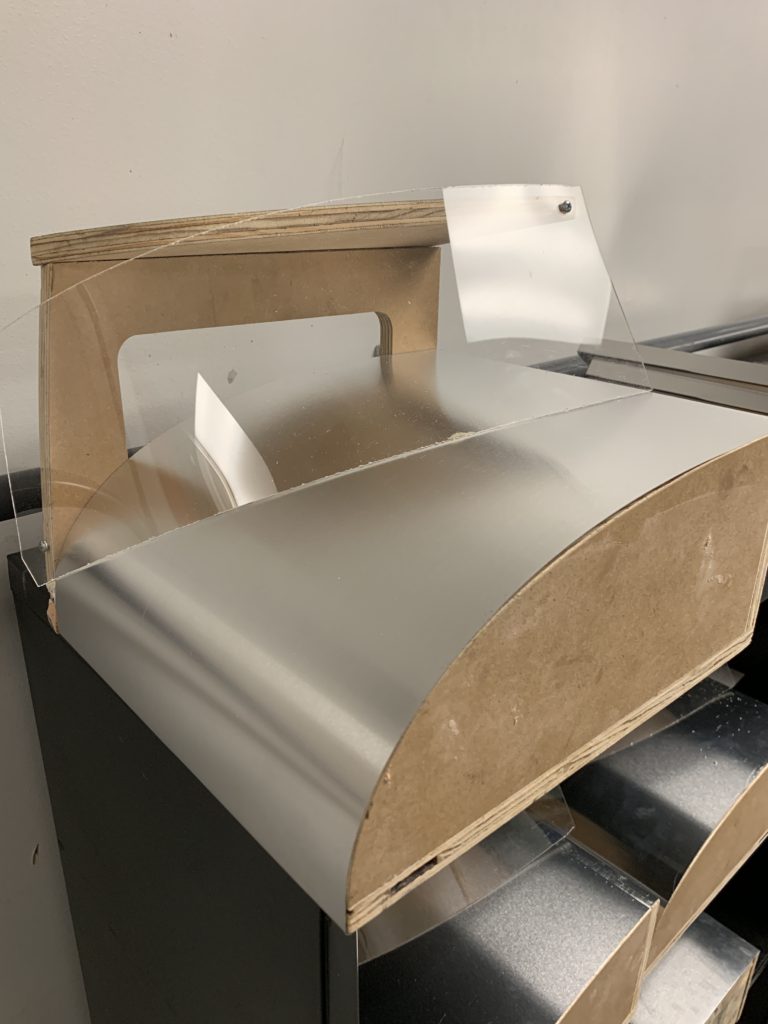

Currently I feel like I’m 90% done and have 90% to go and slowly trying to chip away at the list of things that need to be done. Short re-cap until I finish publishing the back-dated updates. Cabin top was attached and windshield and back windows were installed. Project was moved to the airport successfully and I did the final assembly (hopefully) of the tail feathers. Doors and door windows are installed and working quite well. I’ll have to remove them one last time to paint the door interiors. Door locks and low-profile handles are installed and fully functional.

Engine was delivered and hung on the airplane. Still need to work with Aircraft Specialty to design the SDS FWF kit and get things wired up. I’m also working with Aircraft Specialty to cut my instrument panel. I’m looking to have a few posts regarding that effort soon. I also purchased most of my avionics as well as the last interior bits, so I think I’m done with almost all of my big ticket purchases. Just need time to get them all installed.

I’m also planning to attend an in-person avionics installation class in July as I’m getting closer to installing the instrument panel. I’ll post a bit of a debrief on that class as soon as I get back. Hopefully more regular updates to come.