Continuing on with Section 28, I had an EPIC priming day and got all of the outstanding items painted (including the last of my wing skins!)

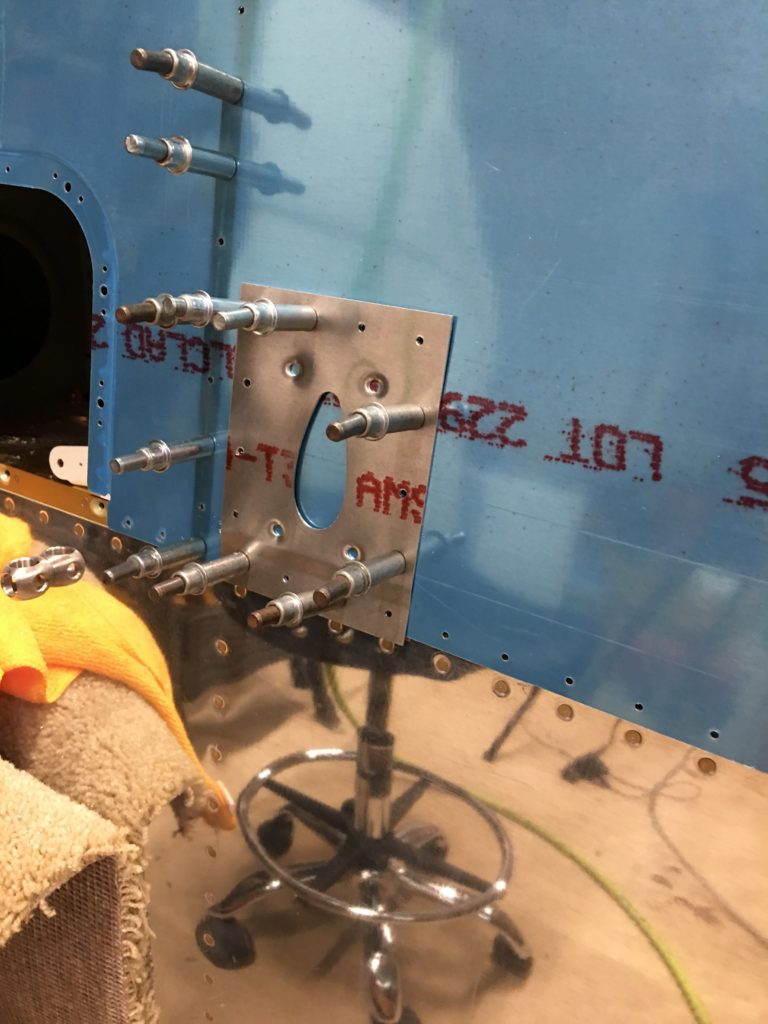

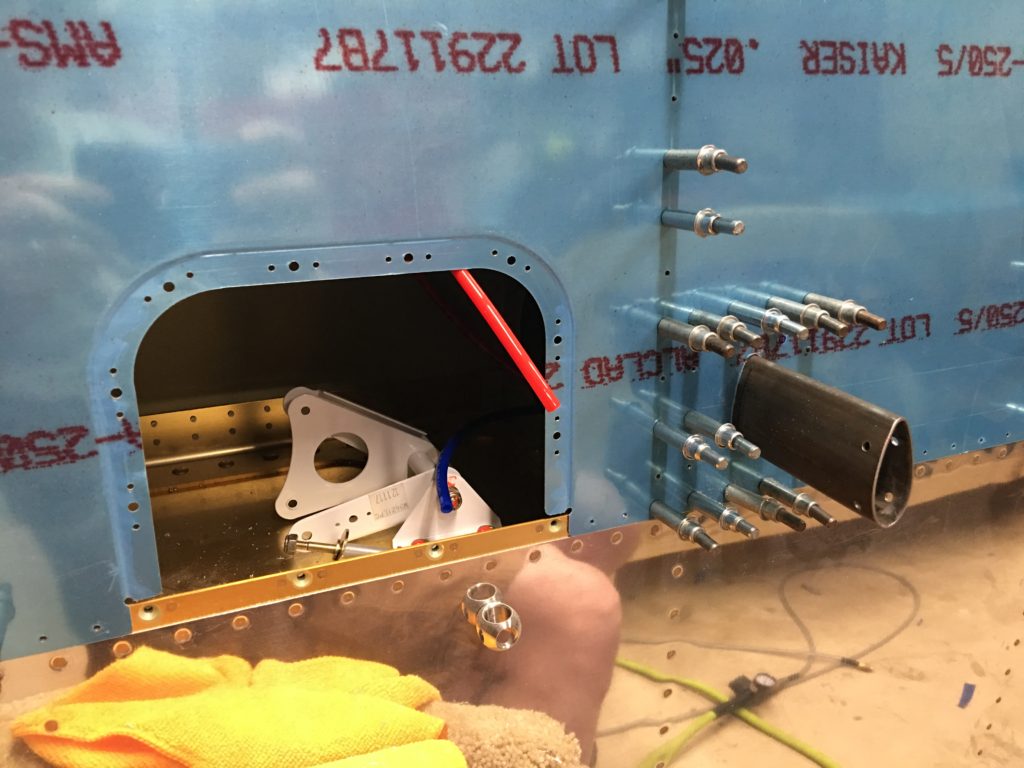

With everything primed, I begin to do the final assembly on all the ribs and bulkheads for the forward fuselage. First step is dimpling all of the parts that will have flush head rivets, then installing rivets in all of the sub-components.

I then pull out my trusty DRDT-2 and begin to dimple the bottom wing skins (after I remove the plastic and deburr). Didn’t catch the larger skin being dimpled, but it’s in the background of my timelapse). I’m basically out of room to move in the garage so I’m about to have a moving day to get the wings into storage.

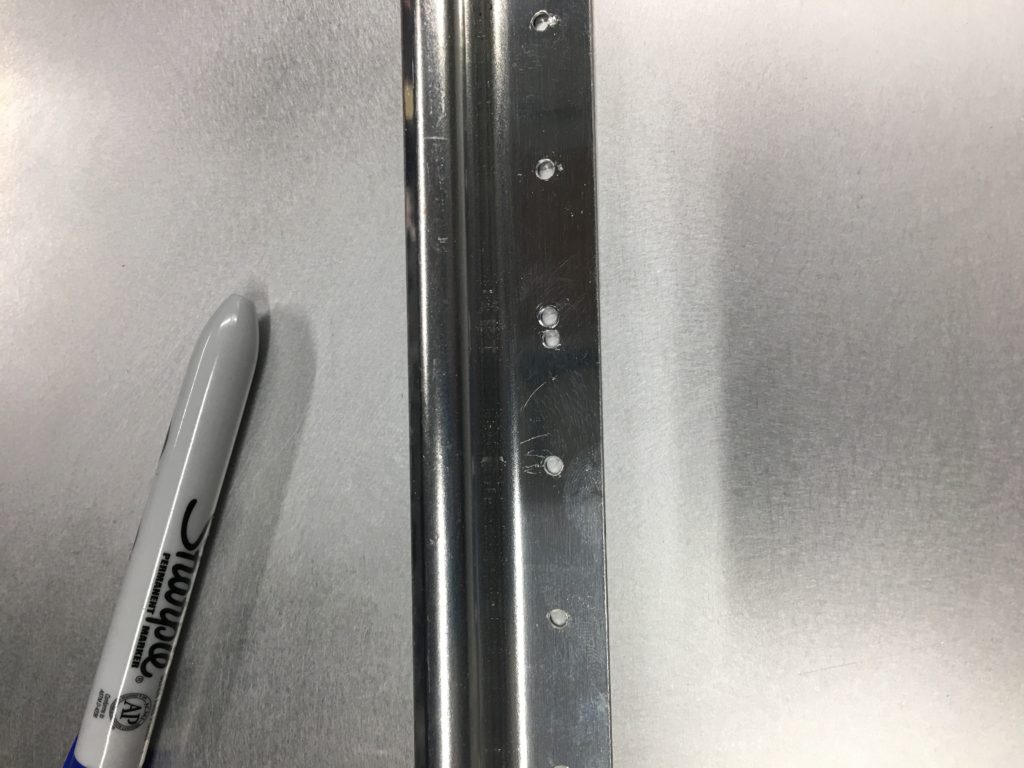

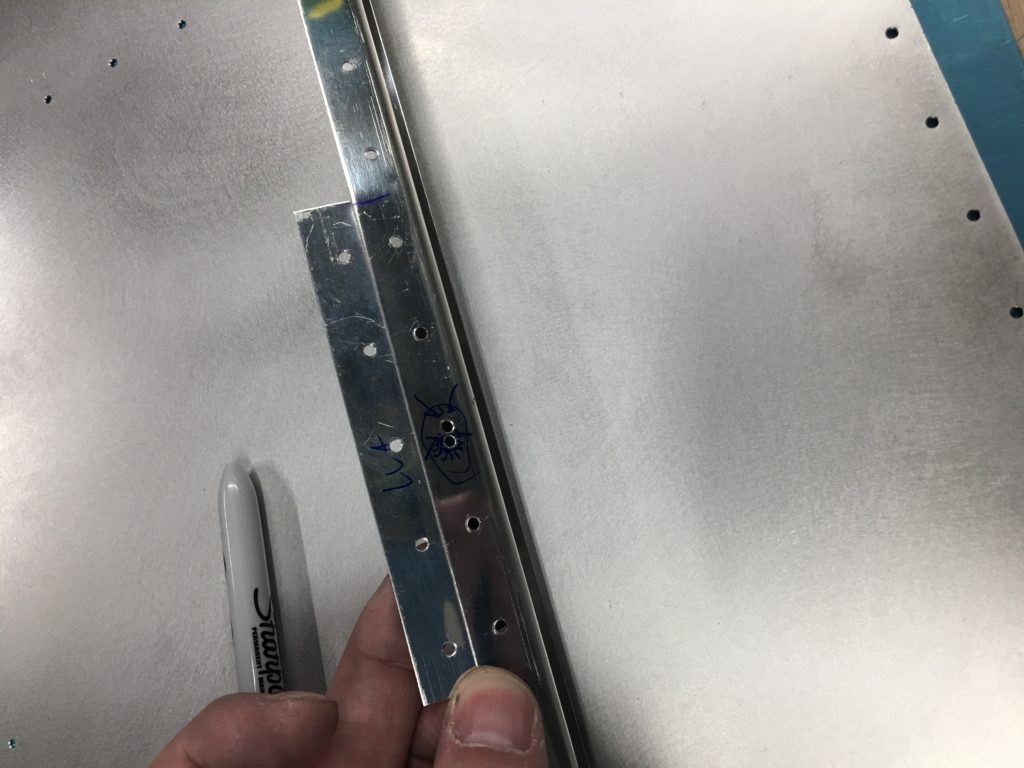

I then complete the dimpling of all of the other components (making sure I take the time to understand what does and does not get dimpled). Then it’s on to prepping the bottom skin so I can back rivet the ribs on. This was very easy and looks great once done. Even got a little assistance from my oldest while I was working on this part.

I decided to order some firewall sealant from skygeek vs using proseal to seal between the skin and the firewall. It looks very much like proseal in the tube, but has a very different consistency when applied to the surfaces. Almost has a foam type of quality to it? Anyway, with the sealant applied, I quickly squeeze those rivets then start to rivet the tunnel to the bottom skins.

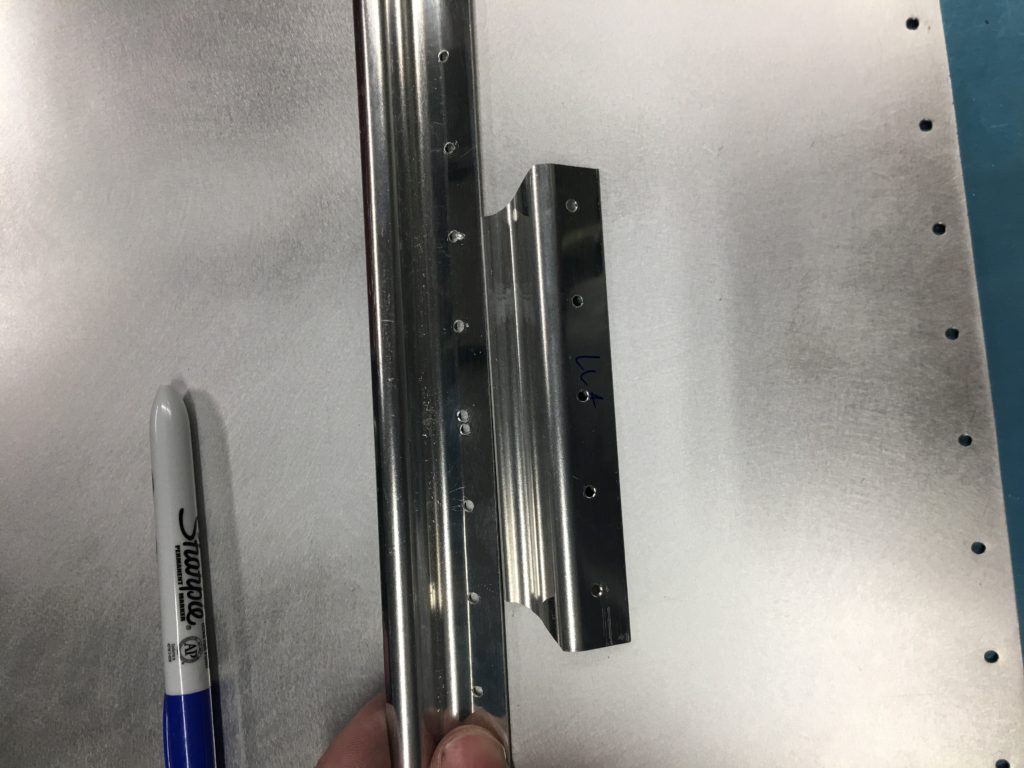

My attempts to back-rivet these parts did not work as planned and I ended up drilling these rivets out I’ll need to call in some favors to help set these rivets before I join the fuse and hopefully move it to the cradle.