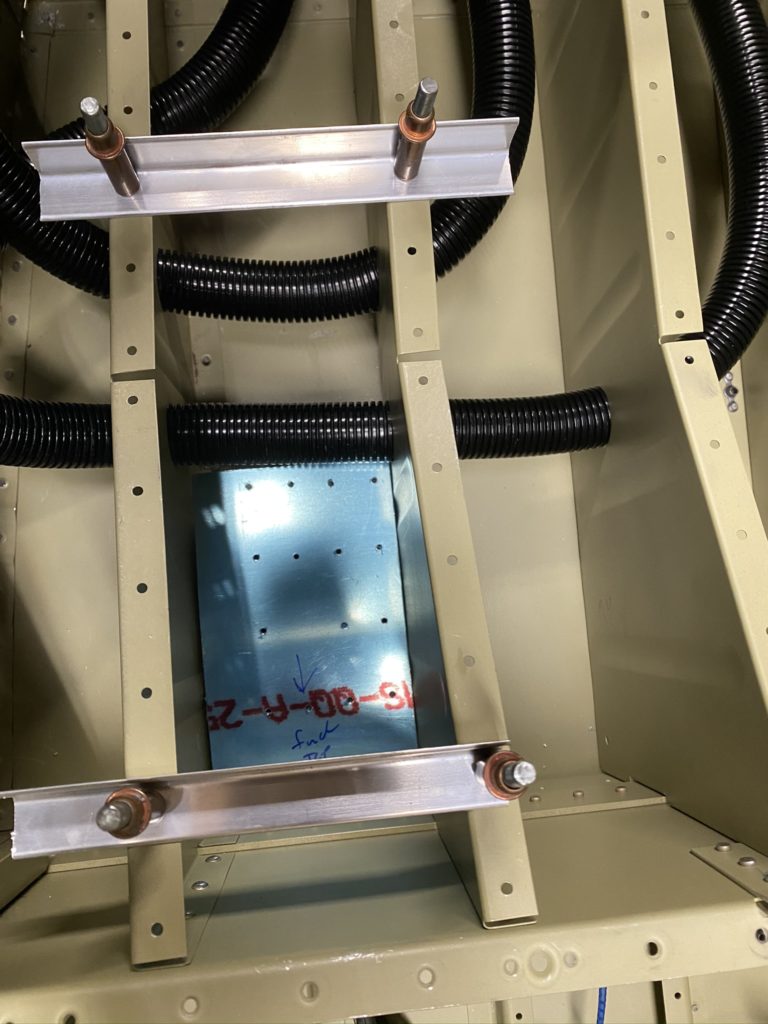

With the conduit run under the rear seat I’m just about ready to install the baggage floor. Looking at the conduit running under the baggage area, it’s obvious it needs to be supported. I don’t have a lot of clever ideas so I end up doing something simple. I use some scrap aluminum and create a support bar that I can zip-tie the conduits to. This is basically a “Z” piece that supports the conduit and keeps things from bouncing around.

I didn’t mention in the last update that I also installed lightening hole mounts for the conduits under the seats and under the door sill so the conduit is supported at the bulkhead behind the rear seat (just in front of the step), the “Z” bracket, and then another lightening hole support at the baggage bulkhead.

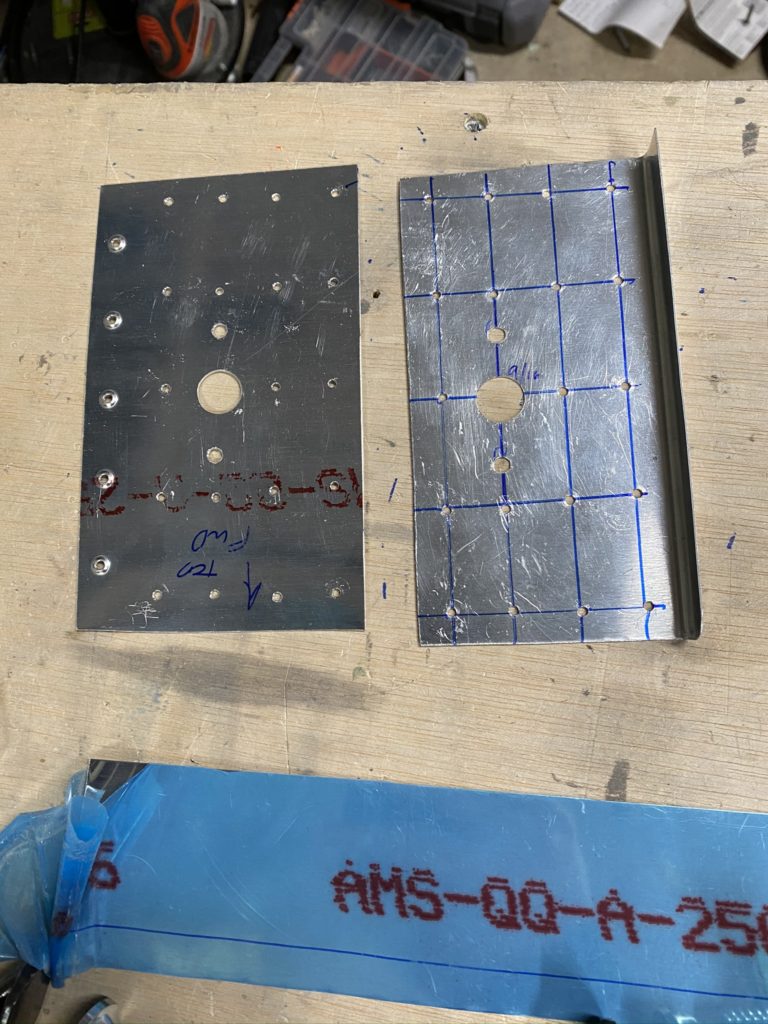

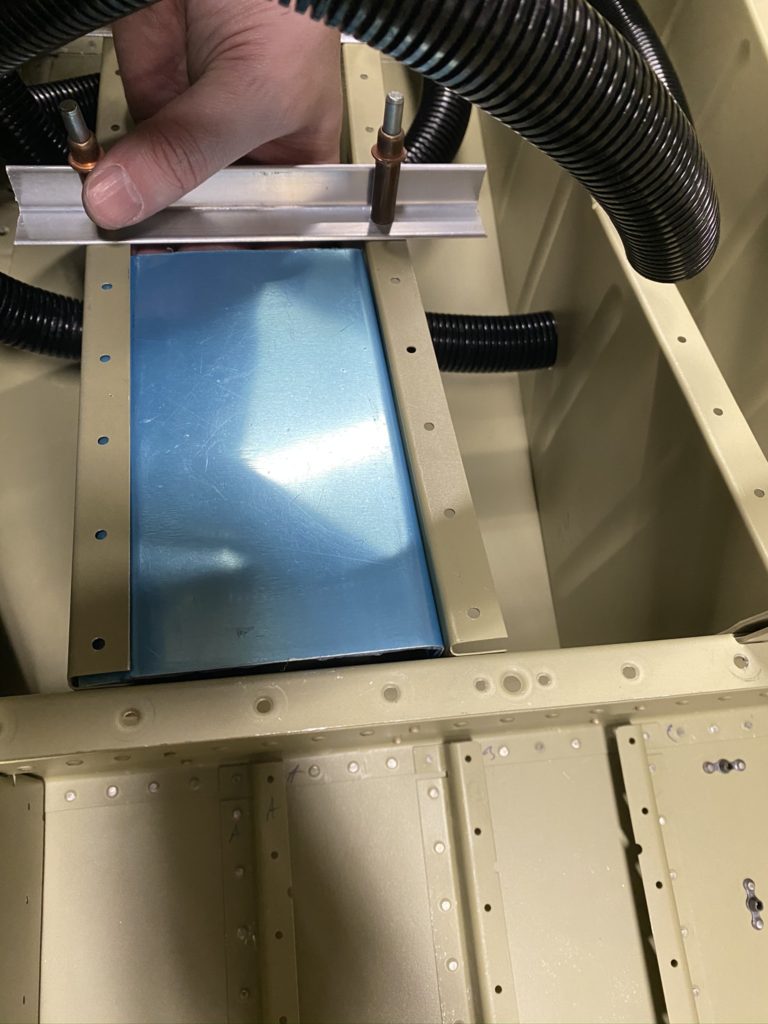

On the left side of the baggage area, I ended up making a slightly better support mount out of angle aluminum and one of the standoffs. I’ll just have to add a step to inspect these using my borescope at my condintion inspections to make sure things supported correctly. If necessary I’ll swap it out but don’t expect any issues.

Added conduit supports

Not pretty, but functional

Zip-tie mounts for the conduit under door sill

Conduits supported under rear seat

A better conduit support for the right side.

All Done.

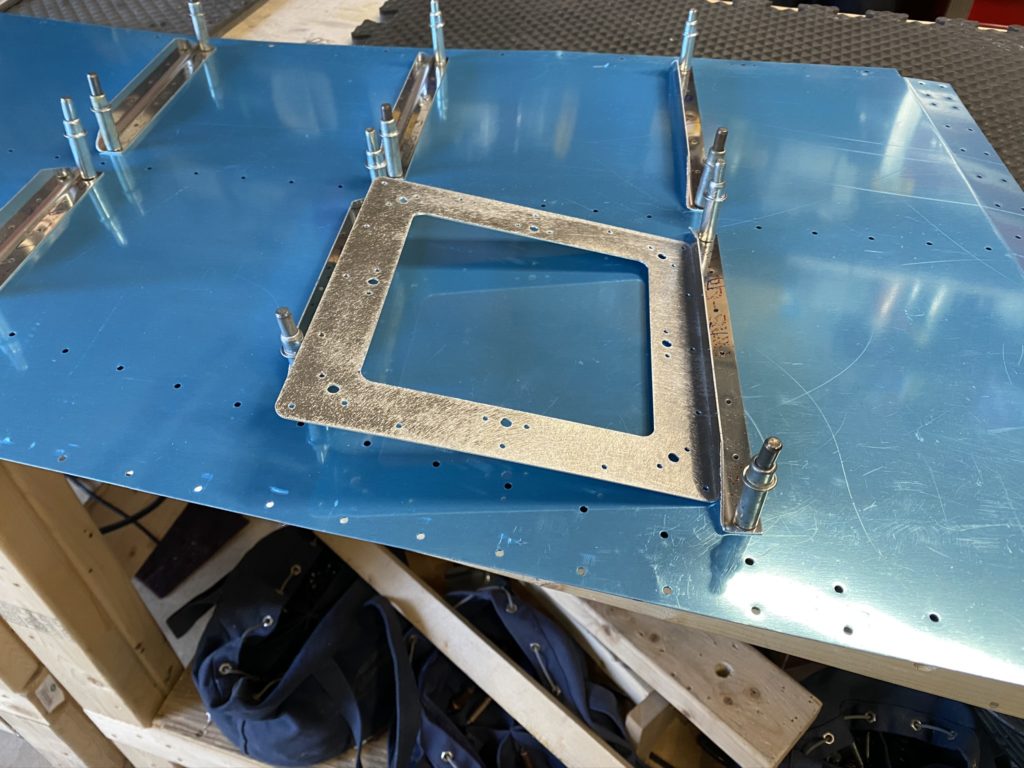

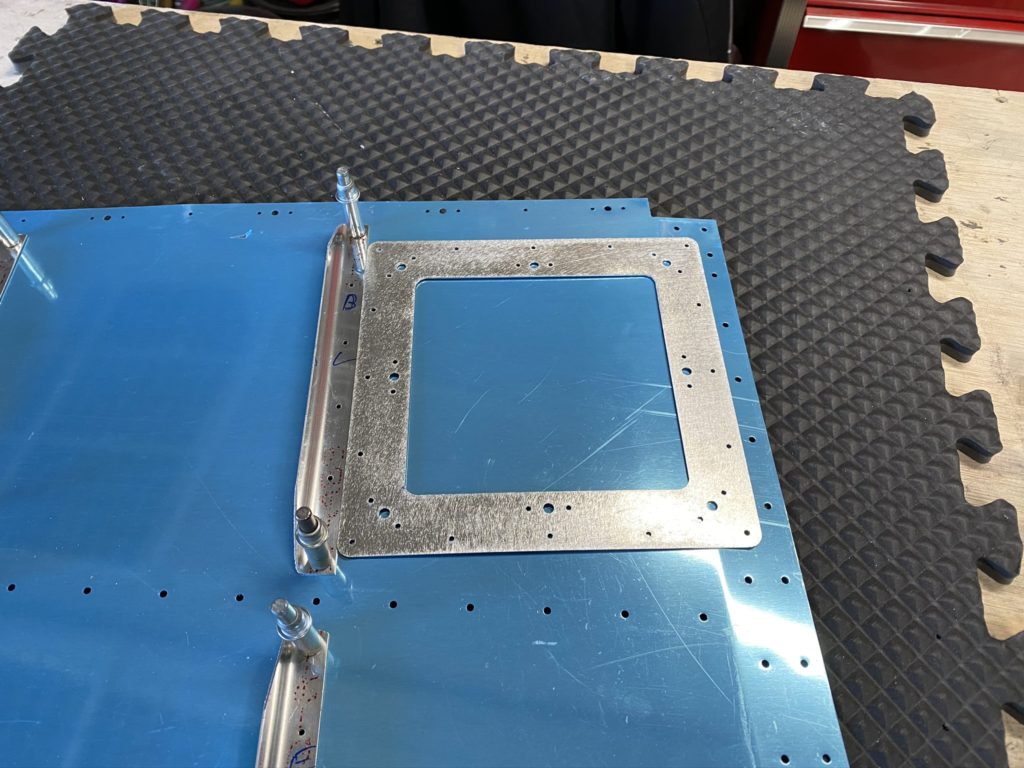

With the conduits installed and supported, it’s time to install the baggage floors and rear seat pans. Besides pulling the conduit through the holes in the rear seat floors, this was not difficult at all. I install the hinge half for the rear seat backs, and rivet the rear seat to the aft bulkhead. I also rivet down the baggage floors with CS rivets per the plans.

At this point I could rivet the rear seats, but as the plans tell you not to, I’m waiting. I think this is to make sure you can access to install antennas or run wires, but I think I have that figured out at this point. Regardless, I’m holding off for a bit just in case something surprises me.

Next step was installing the side panels for the right side of the baggage compartment. I trimmed off the nub and set the panel in place. Next was installing the baggage bulkheads and match drilling the holes. I misread the directions and didn’t have my side panel clecoed properly in place, so that one hole that matches with the bulkhead needed to be “adjusted”. Luckily there is a nutplate installed behind it, so I should be fine.

Drill all the holes in the bulkhead to structure underneath, then use the nutplate jig to drill the nutplate attach holes. At this point it’s pretty routine. Get everything drilled, deburred, and painted. I didn’t install the seatbelt harness stuff yet, as I have to figure out some modifications to the rear baggage bulkhead for the airconditioner hookup.

This basically completes this section but I put a reminder to revisit a few items as I get closer to the end of the build.